Contact Us

Contact Details

-

Address

14, Jalan Sungai Batu Enam 50,

Klang Utama, 42100 Klang,

Selangor, Malaysia

-

Call Us

-

WhatsApp

-

Mail Us

+6012-2107616

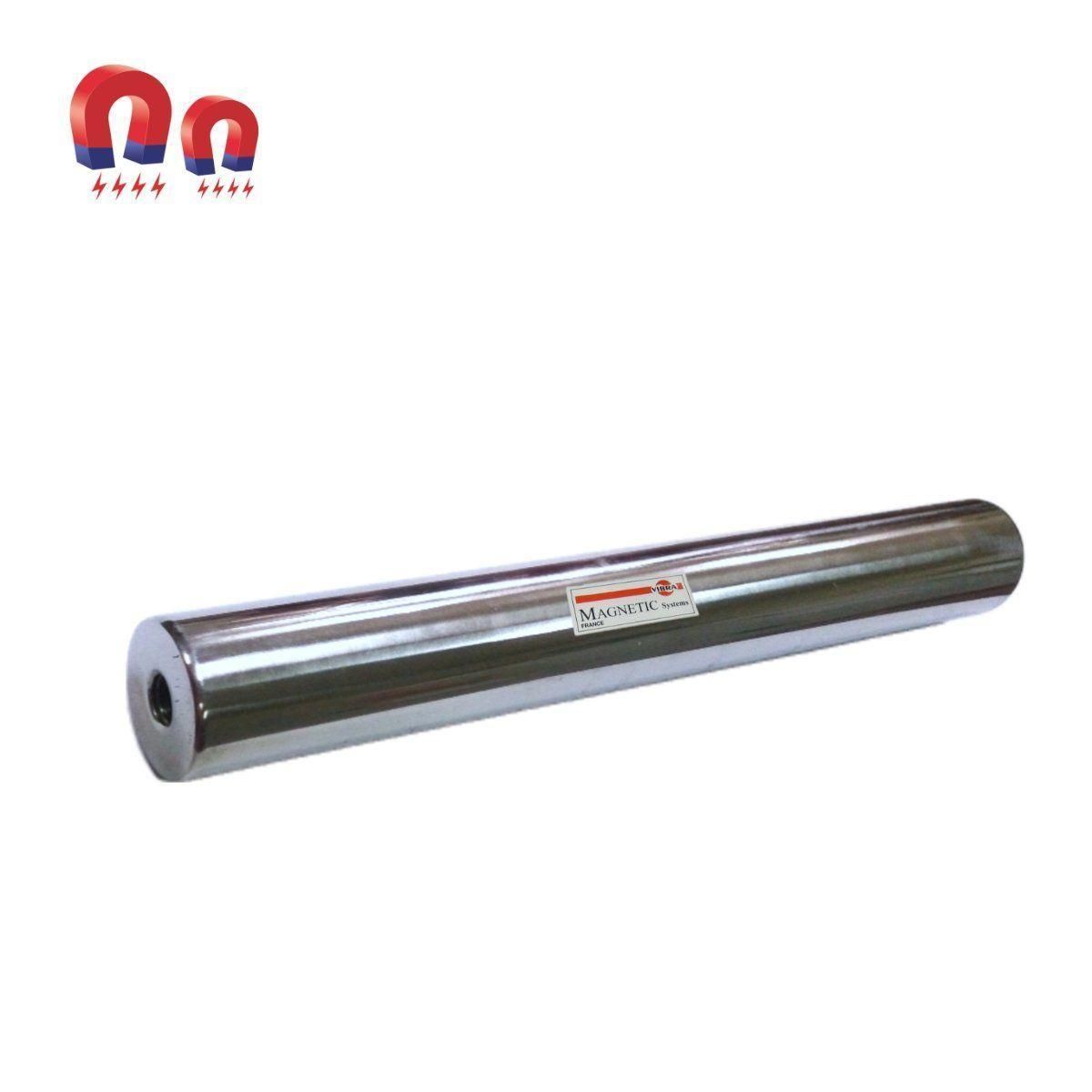

Explore the 5 Advantages of Rod Magnets in Food Manufacturing

Rod magnets are indispensable tools within food manufacturing, offering many advantages that significantly enhance efficiency and safety in production processes. In an industry where precision and sanitation are essential, rod magnets emerge as essential components to maintain them, seamlessly integrating into various manufacturing stages.

Their magnetic properties greatly benefit the food manufacturing industry, offering contamination control for improved outcomes and increased productivity and efficiency. These magnets also help protect equipment in the manufacturing process, which in turn saves manufacturers time and money.

In this article, we’ll explore the 5 advantages of rod magnets in food manufacturing and unveil how they have revolutionised the industry. From preventing equipment damage to enhancing product purity, these magnets are instrumental in upholding the highest standards of food safety and quality assurance.

Contamination Control

Contamination control stands as the biggest advantage of rod magnets in food manufacturing. Rod magnets ensure product purity by effectively capturing ferrous contaminants from raw, free-flowing materials and processing equipment, meeting stringent industry standards.

This proactive approach minimises the risk of contamination-related recalls, safeguards consumer health, and preserves brand integrity. In an industry where quality is non-negotiable, rod magnets emerge as indispensable tools for maintaining impeccable contamination control throughout the production process.

Improved Product Quality

Many food manufacturers face the challenge of ensuring consistent product quality. Rod magnets alleviate this challenge by effectively removing ferrous contaminants from raw, free-flowing materials and production lines.

By eliminating these impurities, manufacturers can enhance the purity and integrity of their products. This not only improves overall quality but also boosts consumer confidence in the safety and reliability of the food they consume.

Enhanced Equipment Protection

There’s a reason rod magnets are used in various industries, from food manufacturing to pharmaceuticals. They provide enhanced equipment protection by preventing damage caused by ferrous contaminants.

They effectively capture fine metal particles from products and materials, safeguarding machineries like mixers and extruders from breaking down or suffering costly damage, thereby preserving production efficiency and minimising operational disruptions. This proactive approach ensures seamless operations, reinforcing the reliability and longevity of essential equipment.

Increased Efficiency

Rod magnets can be found in almost every step of the food manufacturing process because they enhance efficiency. By helping to remove contaminants and prevent equipment damage, rod magnets significantly minimise production downtime.

Their seamless integration into production lines streamlines operations, allowing uninterrupted processing and ensuring timely delivery of high-quality products to consumers. This reliability makes them necessary for maintaining productivity and consumer trust in the competitive food industry landscape.

Cost Savings

With all the advantages listed above, the only end result is how rod magnets in food manufacturing lead to significant cost savings, which in itself is also an advantage. These magnets optimise production efficiency while lowering operational expenses by preventing equipment damage, reducing downtime, and minimising product waste.

Rod magnets’ longevity and reliability translate into long-term savings, making them a wise investment for any food manufacturing facility looking to streamline processes and improve the bottom line. Their cost-effectiveness extends beyond immediate savings, positioning them as indispensable assets in the pursuit of sustainable profitability.

Looking for rod magnets in Malaysia?

If you’re looking for rod magnets in Malaysia, look no further than Sematic Magnet. With food standard options and customisation available, trust us to provide quality magnets for various applications and specifications in the food industry.

Experience an optimised and efficient food operation system and production process with our rod magnets.

Contact us today to learn more about what you need, and our experts will help you choose the ideal magnet solution for your problem.

Sematic Magnet Sdn. Bhd. specializes in consulting, providing solution, designing, and supplying full range of permanent magnetic separation systems, industrial permanent magnetic products, magnetic tools, electromagnet, magnet materials, electrical vibrators, pneumatic vibrators ,and other magnetic equipments.

Quick Links

Contact Us

+6012-2107616

©2022 Sematic Magnet Sdn Bhd. All Rights Reserved. Website Designed by Heroes Of Digital