Contact Us

Contact Details

-

Address

14, Jalan Sungai Batu Enam 50,

Klang Utama, 42100 Klang,

Selangor, Malaysia

-

Call Us

-

WhatsApp

-

Mail Us

+6012-2107616

5 Custom-Made Magnets for Improved Food Safety Standards

Food is essential in our everyday lives. It fuels us for the day and can even keep us satisfied and happy. Because of its significance, the food industry is constantly experimenting and evolving to discover new and better ways to ensure our food is healthy, clean, and safe.

One crucial innovation the food industry has implemented in its production and manufacturing process to ensure food safety standards are up to par is custom-made magnets. These magnets come in various shapes, sizes, and magnetisation strengths and are designed to remove metal contaminants from food products during any step of the production process.

In this article, we’ll explore the 5 common types of custom-made magnets in Malaysia’s food industry, delving into their importance, unique characteristics, and more. Keep reading to discover how these custom magnets help improve food safety, enhance production efficiency, and maintain high-quality food manufacturing standards.

Importance of Custom-Made Magnets in the Food Industry

Magnets are crucial in various industries, including the food industry, to ensure product and consumer safety. The food industry employs magnets in various steps of the production process, from raw material inspection to final packaging.

As technology has advanced, custom-made magnets have become increasingly important due to their tailored designs, which address specific contamination risks unique to different food products and production environments.

Unlike standard magnets, custom-made magnets can be designed with specific shapes, sizes, and magnetisation strengths to fit seamlessly into existing equipment and processes. This precision ensures more effective removal of metal contaminants, enhancing food safety and protecting consumers from potential hazards.

5 Custom-Made Magnets for Improved Food Safety Standards

With the ever-evolving food industry, custom-made magnets in Malaysia are in demand more and more. Not only is it to ensure that food safety standards are consistently met, but these magnets also ensure a more efficient and seamless production process.

To learn about the types of custom-made magnets commonly used in the food industry, here are 5 examples.

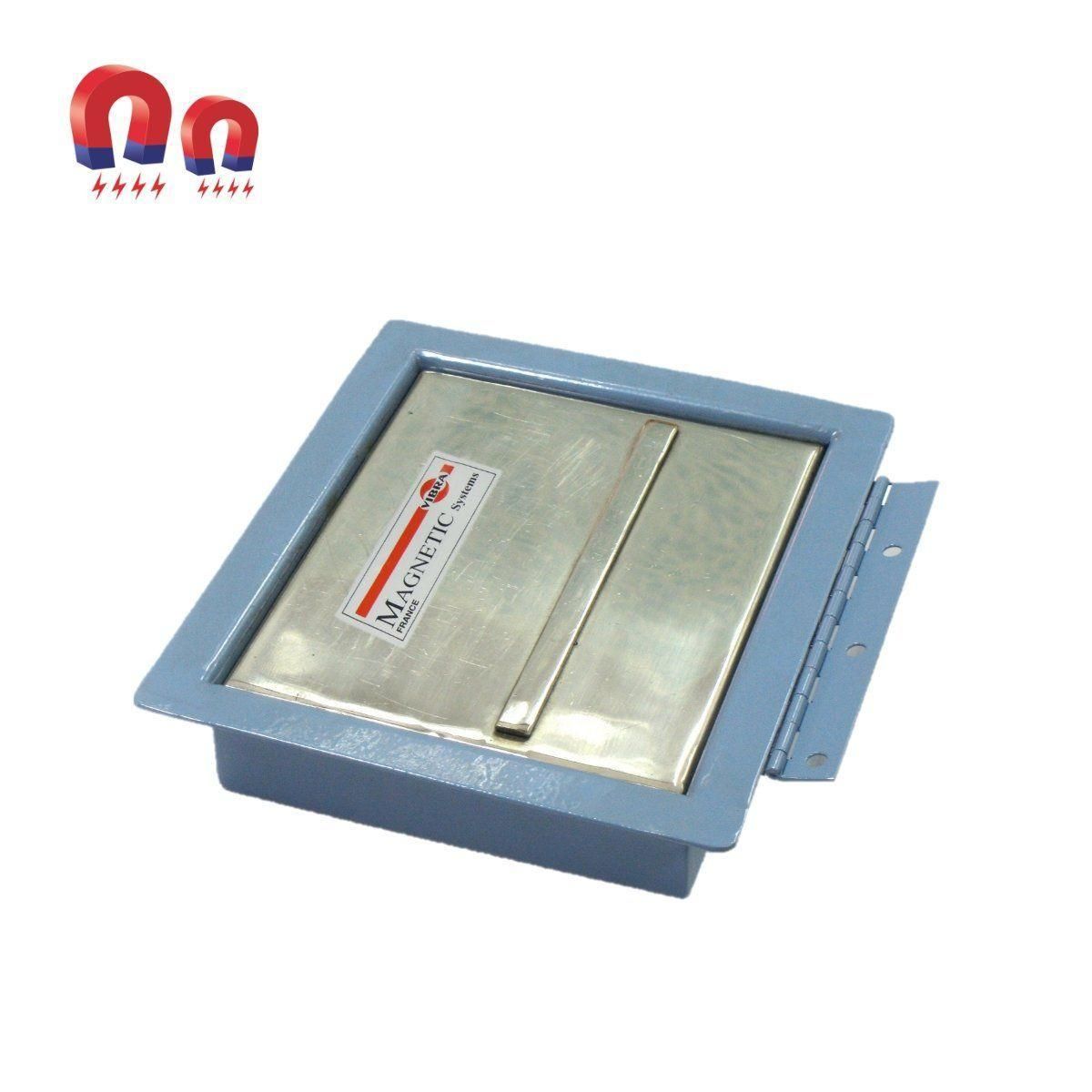

Plate Magnet

Plate magnets are among the most common custom-made magnets in the food industry. Commonly used for inclined chutes or conveyor belts, they come in a variety of shapes and sizes that can be customised to your specific preferences.

Additionally, its magnetisation strength can also be customised, depending on the unique circumstances of your food production. They are easy to install, clean, and maintain, thus making them highly effective magnets in the food production process.

Rod Magnet

You can find rod magnets in various applications in the food industry, but they are commonly found in the initial stages of the food production process, such as during the inspection and cleaning of raw materials.

Rod magnets offer excellent efficiency in removing ferrous contaminants in free-flowing products like granular, liquid, and slurries. They are often made of rare-earth or ceramic magnet materials, which can be customised to your needs.

Grate Magnet

Grate magnets, or magnetic grids, are another common custom-made magnet. Their efficient grid structure helps improve food safety standards by removing ferrous contaminants in dry products, such as sugar, powdered milk, and flour.

Each magnet rod or bar in grate magnets is commonly made from neodymium because of its strong magnetic properties. This is to ensure the effective capture and removal of even the smallest metal particles for a high level of purity, as these magnets are found at the final stages of the production process.

Bullet Magnet

As their name suggests, bullet magnets are cylindrical in shape. They are usually applied within a pipeline system, where they remove ferrous metal impurities as food flows through them. Because they are to be installed within a pipeline system, these magnets are often custom-made to suit the production’s needs.

They are mostly used in dry and free-flowing food, like grains, spices, and flours. One factor that makes them stand out compared to others is their streamlined design, which minimises the disruption of product flow while maximising the magnetic field’s contact with the food, ensuring efficient and thorough removal of contaminants.

Rotary Magnet

Lastly, rotary magnets are also a common custom-made magnet in the food industry. They are essential for ensuring food safety in processing processes involving sticky or clumpy products, such as powdered milk or spices.

Their rotating action prevents product buildup on the magnetic rods, maintaining a consistent flow and efficiently removing ferrous contaminants from difficult-to-flow products. Additionally, their design improves cleaning efficiency, reduces downtime, and ensures a higher standard of food safety and quality.

Looking for custom-made magnets in Malaysia?

If you’re looking for custom-made magnets in Malaysia to improve the food safety standards in your production, Sematic Magnet has got you covered. We offer a wide range of high-quality magnets in various shapes, sizes, grades, and magnet materials designed to meet diverse application needs.

Contact us today to learn more about what you need, and our experts will provide you with advice and guidance for your magnetic application to ensure the right solution for your applications and industries.

Sematic Magnet Sdn. Bhd. specializes in consulting, providing solution, designing, and supplying full range of permanent magnetic separation systems, industrial permanent magnetic products, magnetic tools, electromagnet, magnet materials, electrical vibrators, pneumatic vibrators ,and other magnetic equipments.

Quick Links

Contact Us

+6012-2107616

©2022 Sematic Magnet Sdn Bhd. All Rights Reserved. Website Designed by Heroes Of Digital