How Neodymium Magnet Aids the Malaysian Food Industry

Not many know the significance of neodymium magnets in the Malaysian food industry. While magnets are important in the food production and manufacturing process, what makes neodymium magnets stand out from the rest?

These powerful magnets, composed of neodymium, iron, and boron, have revolutionised various aspects of food processing in Malaysia. From enhancing efficiency in separating metal contaminants to improving the precision of packaging machinery, their impact spans across quality control measures and operational efficiencies.

This article explores how neodymium magnets have become indispensable tools in ensuring food safety and operational excellence within Malaysia’s diverse food manufacturing landscape. By understanding their unique role, you can gain insights into the transformative potential of advanced technology in safeguarding consumer health and enhancing production efficiency.

What are Neodymium Magnets?

Neodymium magnets are powerful permanent magnets made from an alloy of neodymium, iron, and boron. Known for their exceptional strength and magnetic properties, they play a crucial role in various processes in the Malaysian food industry, such as metal contaminant detection and removal and ensuring product purity and safety.

Their ability to efficiently extract ferrous materials from food production lines enhances quality control measures, preventing contamination and safeguarding consumer health. Moreover, neodymium magnets optimise packaging and sorting operations, improving overall efficiency in food manufacturing processes across Malaysia.

What are Neodymium Magnets?

Neodymium magnets offer excellent reliability and performance, contributing significantly to maintaining high standards of food safety and operational excellence in the Malaysian food industry.

If you would like to delve deeper into neodymium magnets’ indispensable role in the food production and manufacturing process, below are 5 ways they contribute.

Versatility in Applications

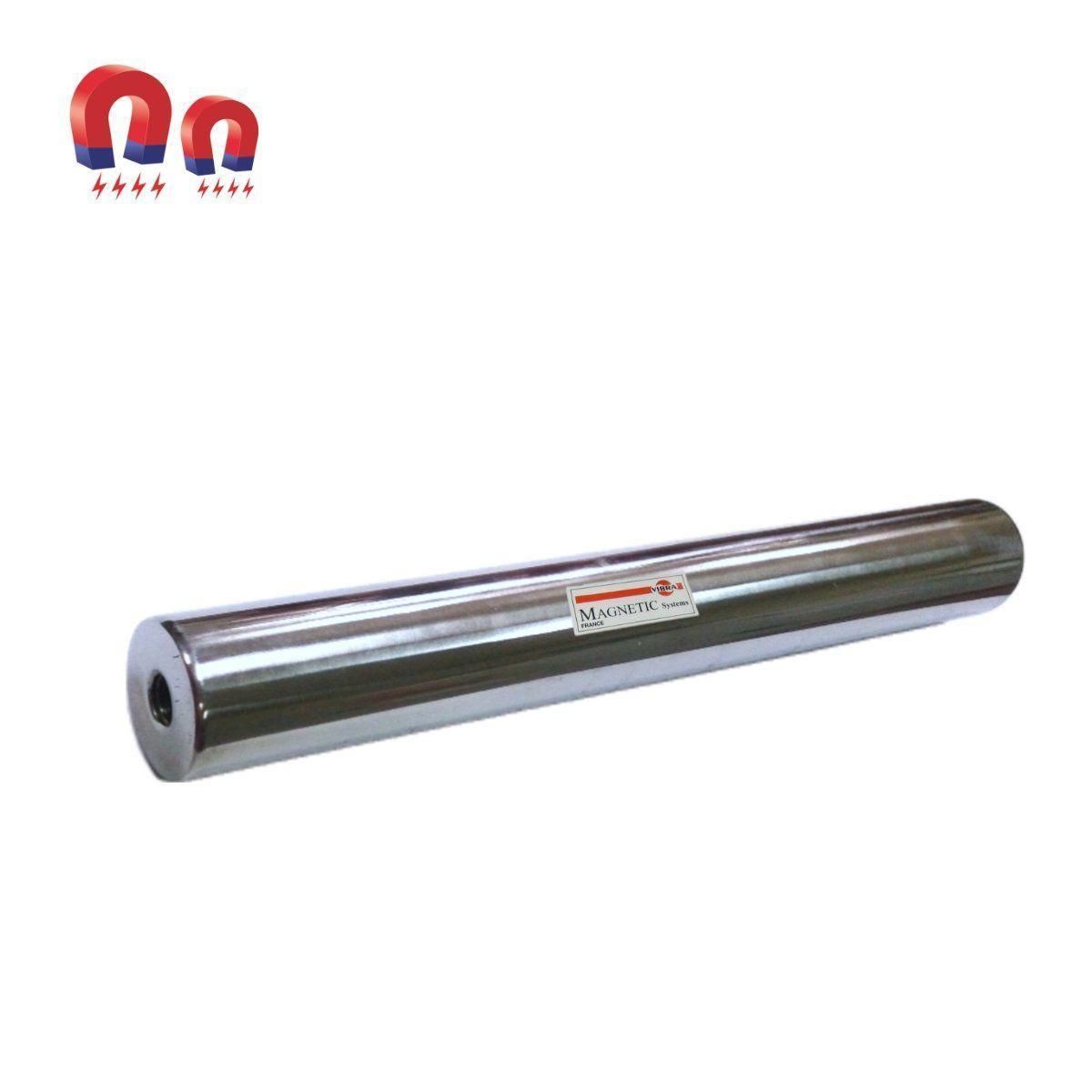

One of the reasons neodymium magnets in Malaysia are indispensable is their versatility in applications. They are used in various food production and manufacturing process stages, from raw material processing to product packaging, and they come in many shapes, sizes, and constructions.

Additionally, you can have it customised to suit your specific needs and preferences. For example, you can have neodymium magnets adapted in the form of grate magnets or rod magnets for any specific application.

Contaminant Removal

Neodymium magnets are considered among the strongest permanent magnets available commercially. With an extremely high magnetic field force, they can attract fine ferrous metal contaminants as tiny as dust particles from free-flowing products, ensuring product purity.

With their efficient contaminant removal capabilities, neodymium magnets are found in every stage of the food production and manufacturing process, from start to end.

Enhanced Quality Control

As mentioned, neodymium magnets are extremely strong permanent magnets, allowing high magnetic fields to be generated. They are applied in every stage of the food production process, further enhancing the quality control of the products.

These magnets effectively remove metal contaminants, ensuring that only pure, safe food reaches consumers. Their precision and reliability minimise the risk of contamination, meeting stringent quality standards in the Malaysian food industry.

Protection of Equipment

Equipment in food production can be vulnerable to wear and tear caused by metal contaminants. Neodymium magnets prevent such damage by effectively capturing ferrous particles, extending the lifespan of processing machinery, and reducing maintenance costs.

Neodymium magnets in Malaysian food industries not only protect the purity of the product but also protect the equipment from damage. This dual function highlights their critical role in maintaining efficient and sustainable operations within the industry.

Increased Efficiency

With neodymium magnets ensuring product purity and equipment protection at every food production stage, it directly increases efficiency. These magnets streamline sorting and packaging processes, reducing production time and minimising errors.

By optimising equipment performance and reliability, they contribute to higher output rates and cost savings, enhancing overall operational efficiency in the Malaysian food industry.

Looking for the right neodymium magnets?

If you’re looking for neodymium magnets to streamline your food production process in Malaysia, Sematic Magnet has got you covered. We offer a wide range of high-quality neodymium magnets in various shapes, sizes, and grades designed to meet diverse application needs.

Contact us today to learn more about what you need, and our experts will provide you with advice and guidance for your magnetic application to ensure the right solution for your applications and industries.