High-Energy VS Recycled Magnetic Bar: Which is More Durable?

Magnetic bars come in various materials, shapes, and sizes, each offering unique benefits and applications. While some magnetic bars are distinctly different to one another, high-energy and recycled magnetic bars in Malaysia barely differ in appearance and composition. But when it comes to durability, which of these seemingly similar magnets stands out?

Understanding the subtle nuances in their performance can reveal surprising distinctions that impact their longevity and suitability for different tasks. Dive in to discover which magnet truly holds up under pressure. Whether you’re a science buff or a practical user, uncovering which type of magnet holds up better under different conditions is an enlightening exploration.

What are High-Energy Magnetic Bars?

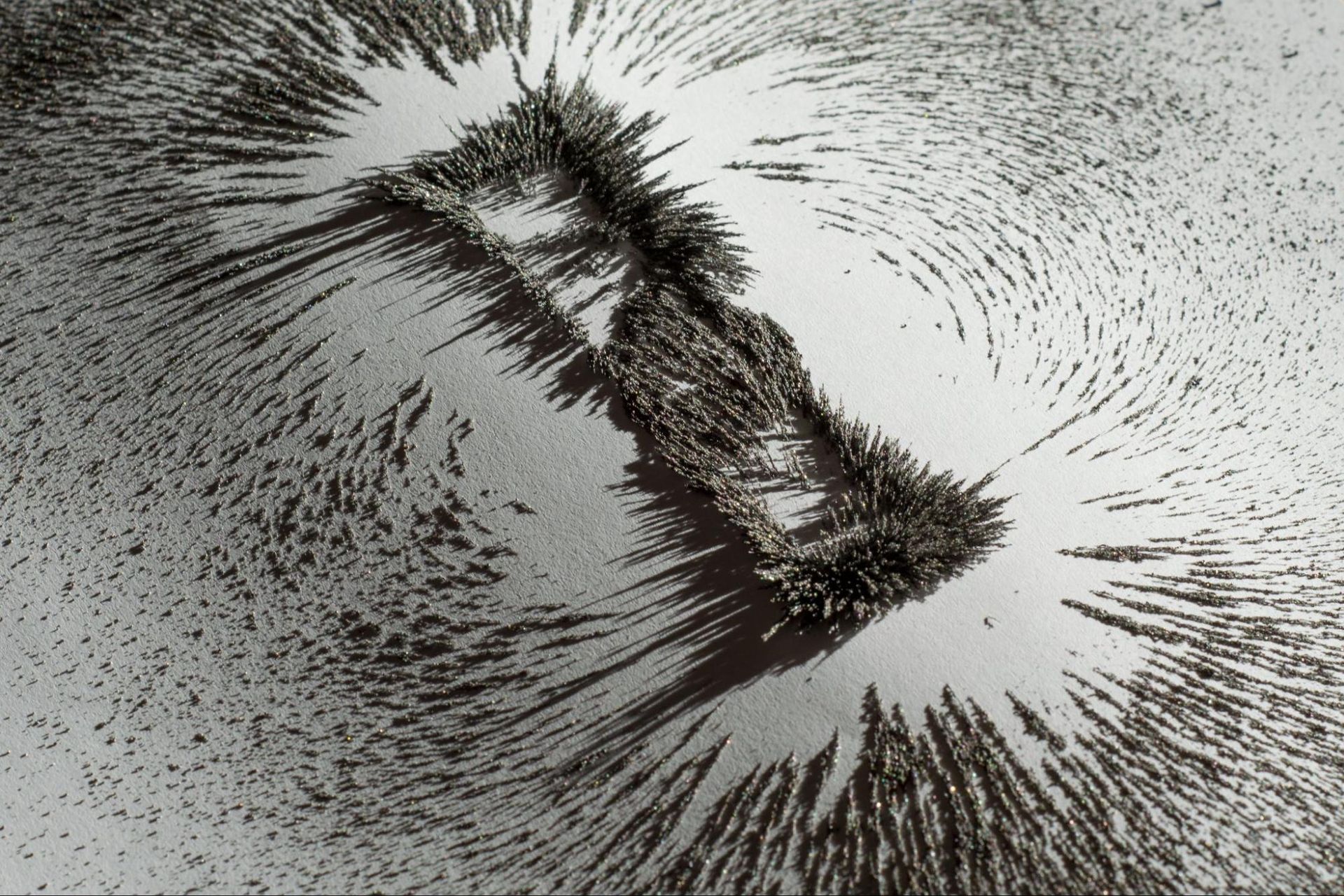

High-energy magnetic bars are typically made from new ferromagnetic materials like iron, cobalt, nickel, or various alloys. Also known as new raw material magnetic bars or rod magnets, these magnets are produced by melting new raw materials to create an alloy. Then, they are crushed and finally sintered into any simple geometric shape, from cylindrical rods and rectangular bars to discs and rings, and magnetised until saturation occurs.

These magnetic bars are commonly used in industrial applications and various magnetic separation processes due to their strong and uniform magnetic field distribution across their composition. Because they use new raw materials, these magnetic bars exhibit enhanced magnetic properties, like generating a powerful magnetic field and have a high coercivity.

What are Recycled Magnetic Bars?

Reflecting their name, recycled magnetic bars are made from recycled magnets that have reached end-of-life. These magnets are composed of recycled rare earth magnets like neodymium, iron, and boron to give them a new life by restoring their magnetic properties through reprocessing.

The recycling process of magnetic bars is straightforward. End-of-life rare earth magnets are melted down before being processed similarly to high-energy magnetic bars and produced into plastic-bonded or hot-formed magnets.

It is also an eco-friendly and cheaper alternative as it doesn’t require the mining of new raw materials to create new magnets, thus reducing environmental impact and conserving natural resources. This sustainable approach not only supports the circular economy but also helps meet the growing demand for rare earth magnets in various high-tech applications.

Which is More Durable?

After learning about high-energy and recycled magnetic bars, it’s time to question their durability. This comparison explores and examines various factors to determine which magnet outlasts the other in various applications.

Comparing Composition

Comparing composition in high-energy versus recycled raw materials magnetic bars involves analysing their material composition and structural integrity. Differences in the types of materials used will affect their resistance to corrosion and demagnetisation.

High-energy magnetic bars are made from new raw materials, thus exhibiting superior and consistent magnetic strength, performance, and durability against stress, wear, and environmental conditions.

On the other hand, recycled raw materials magnetic bars may have slightly varied properties due to the reprocessing of materials, even if the same material is used in high-energy ones. Because the recycling process includes impurities, they might potentially differ in performance, structure, and longevity.

Longevity in Different Applications

Longevity in different applications between high-energy and recycled raw materials magnetic bars varies based on factors like exposure to moisture, temperature fluctuations, and mechanical stress.

High-energy magnetic bars have a more consistent magnetisation pattern and design, resulting in a more consistent magnet strength and magnetic field. In contrast, recycled raw materials magnetic bars are inconsistent and impure in composition, resulting in faster demagnetisation and weaker overall magnetic properties. However, each magnetic bar can thrive depending on the application.

Factors Affecting Durability

Several key factors influence the durability of high-energy versus recycled raw materials magnetic bars. Factors such as intended application, magnetisation method, and exposure to external forces all play critical roles in determining which magnet type withstands wear and tear better over time.

Here are more factors that thoroughly examine each magnet’s durability:

- Ability to Withstand High Temperature: Differences in composition can impact a magnetic bar’s ability to withstand high temperatures. While both can withstand temperatures up to 80°C, magnetic bars using recycled raw materials may not withstand long-term usage.

- Efficiency in Attracting Iron Particles: For long-lasting effectiveness, efficiency in attracting iron particles depends on a strong and uniform magnetic field. For example, high-energy magnetic bars might be the most efficient due to their consistent magnetic field distribution.

- Usage Conditions: Considerations such as temperature, humidity, and exposure to abrasive materials play a significant role in determining durability. High-energy magnetic bars are more resilient and consistent in maintaining their performance under high-stress conditions than magnetic bars made from recycled raw materials.

- Application-specific Demands: The specific tasks and environments in which the magnets are employed can highlight strengths or weaknesses unique to each type, influencing their overall durability and effectiveness. Magnetic bars made of recycled raw materials, for example, are often used in wind turbines for their effectiveness while still being sustainable.

Where to get magnet supply in Malaysia

Determining which is more durable between high-energy and recycled magnetic bars can be difficult, especially when considering their diverse applications. Rather than a straightforward comparison, it is more important to assess the suitability of a specific application, ensuring you’re selecting the most durable option tailored to the application's demands.

If you’re looking for a magnet supply, like a magnetic bar, in Malaysia, look no further than Sematic Magnet. We offer a variety of magnets in various shapes and sizes to suit your diverse needs. Contact us today to find which magnet is the right one for you.