Contact Us

Contact Details

-

Address

14, Jalan Sungai Batu Enam 50,

Klang Utama, 42100 Klang,

Selangor, Malaysia

-

Call Us

-

WhatsApp

-

Mail Us

+6012-2107616

How Long Should Industrial Magnets Last?

When you purchase something, one of the top considerations is, “How long will this product last?” The same principle also applies to industrial magnets. They have been around for centuries and have various benefits across different industries, ranging from the healthcare and automobile industry to recycling and electronics, proving that magnets aren’t just something you stick on your fridge.

When choosing the right industrial magnets, it’s not just about strength but longevity as well. What happens when these magnets start to lose their magnetic properties too soon? It will likely result in costly downtime and repairs. In this blog, we’ll examine what causes magnet demagnetization and how you can prevent one. Before we delve into all that, let’s define what industrial magnets are.

What Are Industrial Magnets?

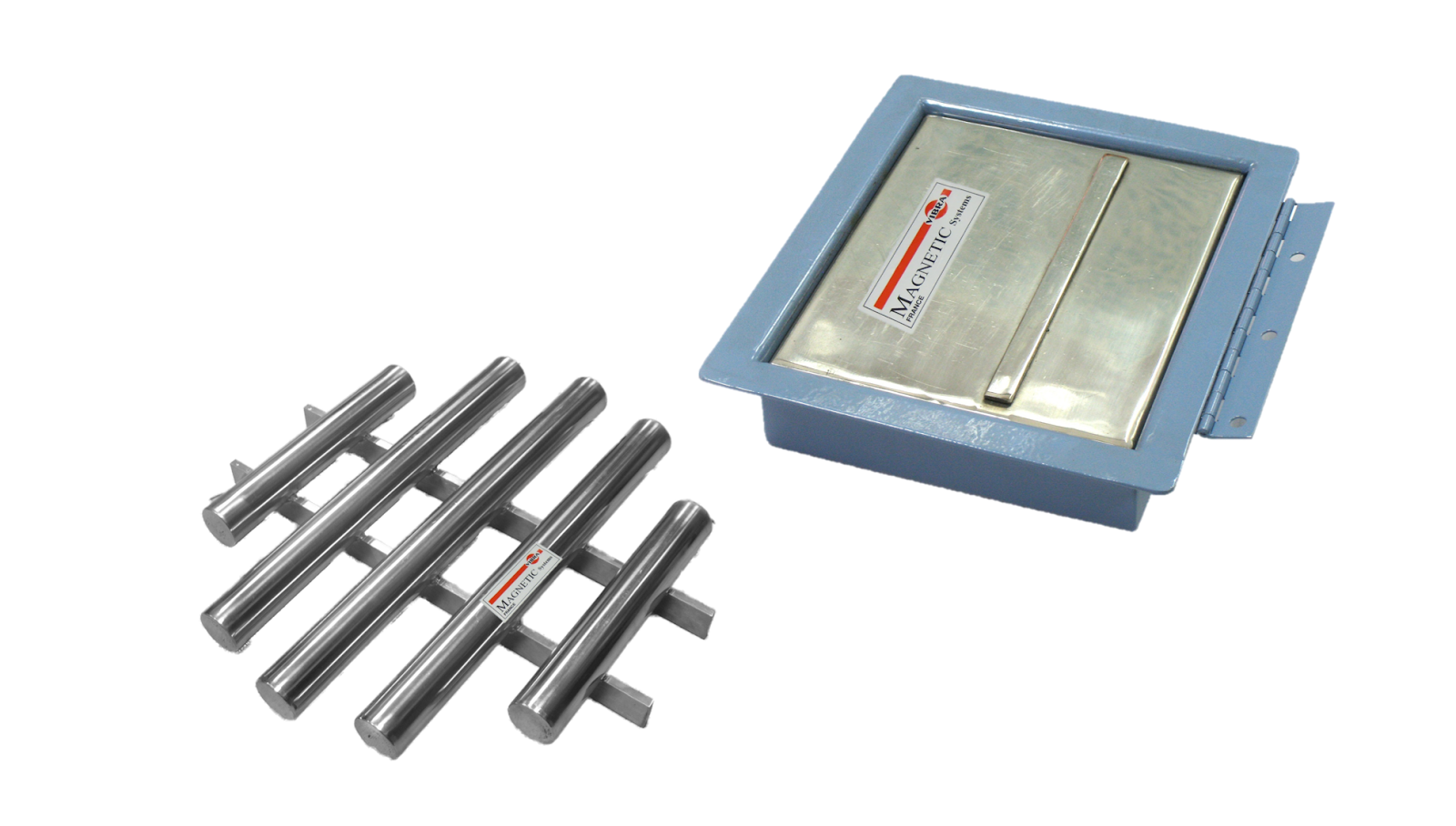

Unlike the household magnets that hold your family picture on the fridge, industrial magnets are much more powerful as they’re used in much harsher conditions, like manufacturing factories or recycling plants. While the basic use or principle is the same—attracting magnetic properties to hold or sort them—the applications vary for different industries. Regardless, industrial magnets are often made of neodymium, samarium cobalt, ceramic, and alnico, known for their strong magnetic properties.

Depending on your needs and usage, industrial magnets are customizable in size and shape. Regarding manufacturing and construction, bar and block magnets are ideal for holding metal parts in place. Ring magnets are suitable for motors and generators. Meanwhile, cylindrical magnets are often used in magnetic sensors.

Finally, the two common shapes that you might encounter in daily life is the sphere and disc magnets, as they’re used in jewellery and closures for windows, fridges, or cabinets

What Are The Common Uses Of Industrial Magnets?

People use industrial magnets to lift and hoist heavy objects like sheet steel, iron plates, and car engines. Magnets also serve as a means of separating desired materials from contaminants in industries such as mining, food production, and recycling. Moreover, magnets are used in electronics such as speakers, microphones, and hard drives to convert electrical energy into mechanical energy or sound waves.

Another example is the food and beverage industry, where industrial magnets are used, especially during packaging. Magnets help to move metal cans or containers from one conveyor belt to another, eliminating the need for manual handling of the containers. This reduces the risk of worker injury and contamination, while also increasing efficiency.

Additionally, magnets are vital in ensuring food safety in the food and beverage industry. They attract metal debris like screws or shavings that may be present by being placed in areas where food and beverage products pass through, collecting metal debris that may have fallen into the product during processing or packaging.

Why do Long-Lasting Industrial Magnets Matter?

Similar to any other product you purchase, a long-lasting industrial magnet can be beneficial for the following reasons:

More economical

These magnets are used in factories for assembly or electronics, so replacing them repeatedly can be expensive. Investing in durable and top-of-the-line industrial magnets may have a higher upfront cost but will pay off in the long run.

More environmentally friendly

Do you know industrial magnets are mostly made of earth materials and metals? The materials are directly mined from the Earth and are non-renewable. Therefore, the process can have a negative impact on the ecosystem. Having long-lasting industrial magnets allows you to mine less, minimising your carbon footprint.

More reliable and consistent

Industrial magnets are used in critical applications like aerospace and medical equipment, where the magnet's reliability is crucial for safety and performance. A long-lasting magnet reduces the risk of failure, ensuring the system will operate as intended for a longer period.

Why Magnets Demagnetise?

While there’s no definitive answer to a magnet’s shelf life, a BBC portal estimated that industrial magnets made of samarium-cobalt take around 700 years to lose half their strength—that can last you multiple lifetimes! However, several contributing factors may accelerate the process:

Heating

Each magnet material has a Curie point, meaning if the magnet is heated to a certain temperature, it loses its magnetisation capability. For example, the Curie point of iron is 768°C, whereas the neodymium is around 80 to 310 °C.

Hammering and dropping

Hammering a magnet on a hard surface can cause the magnetic domains in the magnet to become disordered, resulting in the magnet losing its magnetisation. The same effect can also be realised by dropping the magnet.

Corrosion

Exposure to corrosive environments like saltwater or acids can cause a magnet to corrode and lose its magnetic strength.

How To Prolong Your Magnets?

Now that you know why magnets can lose their magnetic properties, how can you prolong their shelf life? Here are three tips.

Handle with care

Consider using protective gear, such as gloves or padding, to handle magnets gently and avoid accidental drops.

Store in a dry place

Magnets are susceptible to corrosion and rust, which will weaken their magnetic properties. Therefore, keeping it in a dry place is crucial. Additionally, you may need to add a protective coating to prevent corrosion in the first place.

Keep away from high temperatures

As stated above, high temperatures cause the magnets to demagnetise, so it’s advisable to prevent prolonged heat exposure.

Where to get Industrial Magnets in Malaysia?

Industrial magnets have many applications across industries. However, their lifespan is equally important as their strength, as it will help you save costs, be more environmentally friendly, and ensure consistent performance.

If you’re looking for

top-quality industrial magnets built to last, look no further!

Sematic Magnet get you covered! We offer various industrial magnets based on size and material to meet your needs.

Contact us today!

Sematic Magnet Sdn. Bhd. specializes in consulting, providing solution, designing, and supplying full range of permanent magnetic separation systems, industrial permanent magnetic products, magnetic tools, electromagnet, magnet materials, electrical vibrators, pneumatic vibrators ,and other magnetic equipments.

Quick Links

Contact Us

+6012-2107616

©2022 Sematic Magnet Sdn Bhd. All Rights Reserved. Website Designed by Heroes Of Digital