Why Magnetic Separators Are Important In The Food Industry

Only several industries have the kind of widespread social impact that the food processing business has. A lot of safety procedures must be in place when a business affects many individuals.

Safety and quality are critical in the food processing industry, especially since the products affect people's health, wellness, and sustenance. While there are various techniques to guarantee high-quality products during the food processing stage, it all begins with reducing the possibility of contamination.

In most businesses, contamination is unacceptable, but it is highly detrimental when working with food products. One of the most prevalent pollutants in food plants is ferrous debris, which a magnetic separator can quickly eliminate.

What Are Magnetic Separators?

Image A

A type of machinery known as a magnetic separator is used to attract and remove foreign metal fragments from other products magnetically. They are often put in a line of moving components for optimal protection against contamination and harm to expensive equipment and can be utilised in conjunction with metal detectors and x-ray machines.

Depending on the product and industry they are designed for, a magnetic separator can have the following:

- A wide range of sizes

- Distinct configurations

- Different operating characteristics

Among the various kinds of magnetic separators are:

- Grate magnets

- Pulley magnets

- Plate Magnets

- Suspension magnets

- Hopper Magnets

- Liquid line magnets

Despite their distinctions, all types were designed with the same goal: to remove undesired metal impurities.

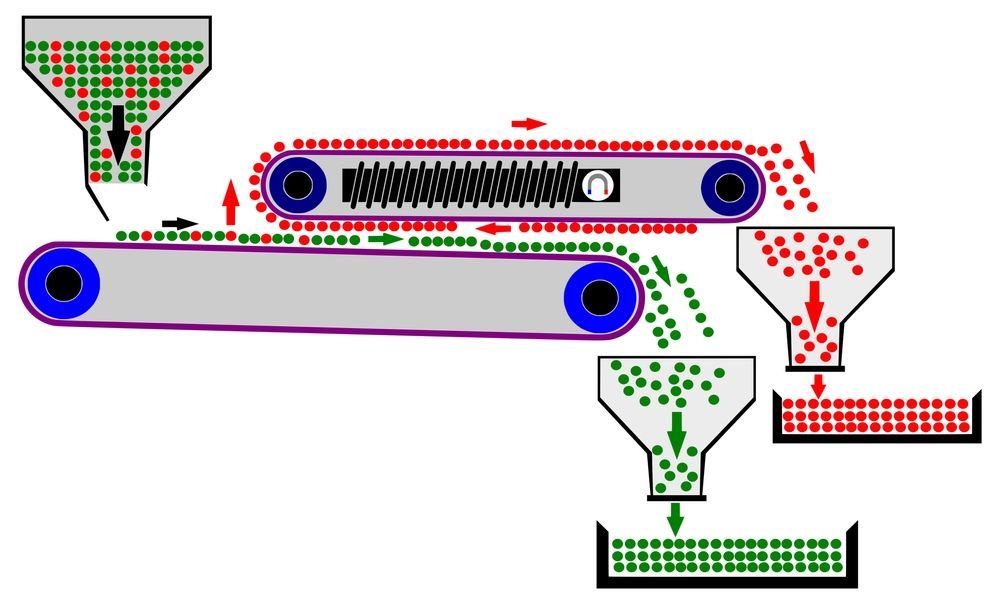

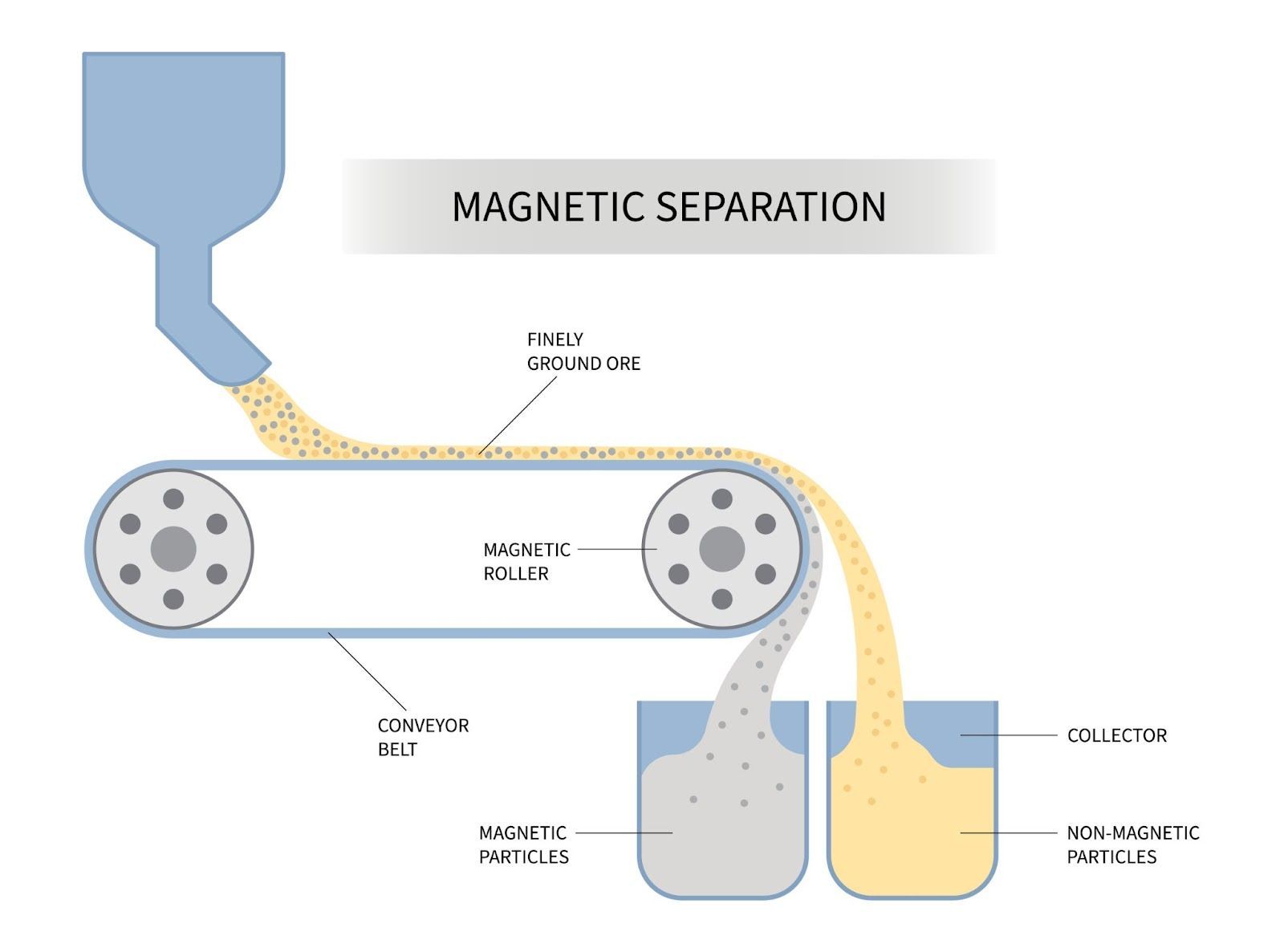

How Magnetic Separators Work In The Food Industry?

These systems use magnets to draw ferrous elements, filter them, and remove them from production. Some ferrous materials can include:

- Iron filings

- Tiny magnetic particles

This process is especially crucial in the food business, where products must be packaged and delivered residue-free. For example, magnetic separators can be fitted to the conveyor belt at any spot along the manufacturing line because they come in a variety of shapes and with various characteristics.

Since high-performance magnetic separators are corrosion-resistant, humidity is not a concern. This is quite practical because they can also be used to remove liquids like oil off surfaces.

Magnetic drums are frequently utilised to capture larger and heavier contaminants in the food processing chain. Permanent magnets and electromagnets may also be included in this system. They are installed on the exterior of the conveyor belts so that anything magnetic that passes over them is instantly attracted.

Examples of use

In food processing, it's crucial to have equipment that can identify and eliminate metal impurities, and magnets are an effective method. Choosing the right magnetic separator involves:

An awareness of magnetic qualities

Product characteristics

Environmental conditions unique to each food processing plant

There are several different designs of magnetic separators, including:

Rod Magnets

There are various uses for rod magnets, which are permanent non-electric magnetic components. Rod magnets like the VIBRA® rod magnets are used to get rid of ferrous impurities that are found in tiny, shallow volumes flowing in products like:

- Powder

- Granules

- Fibres

- Liquids

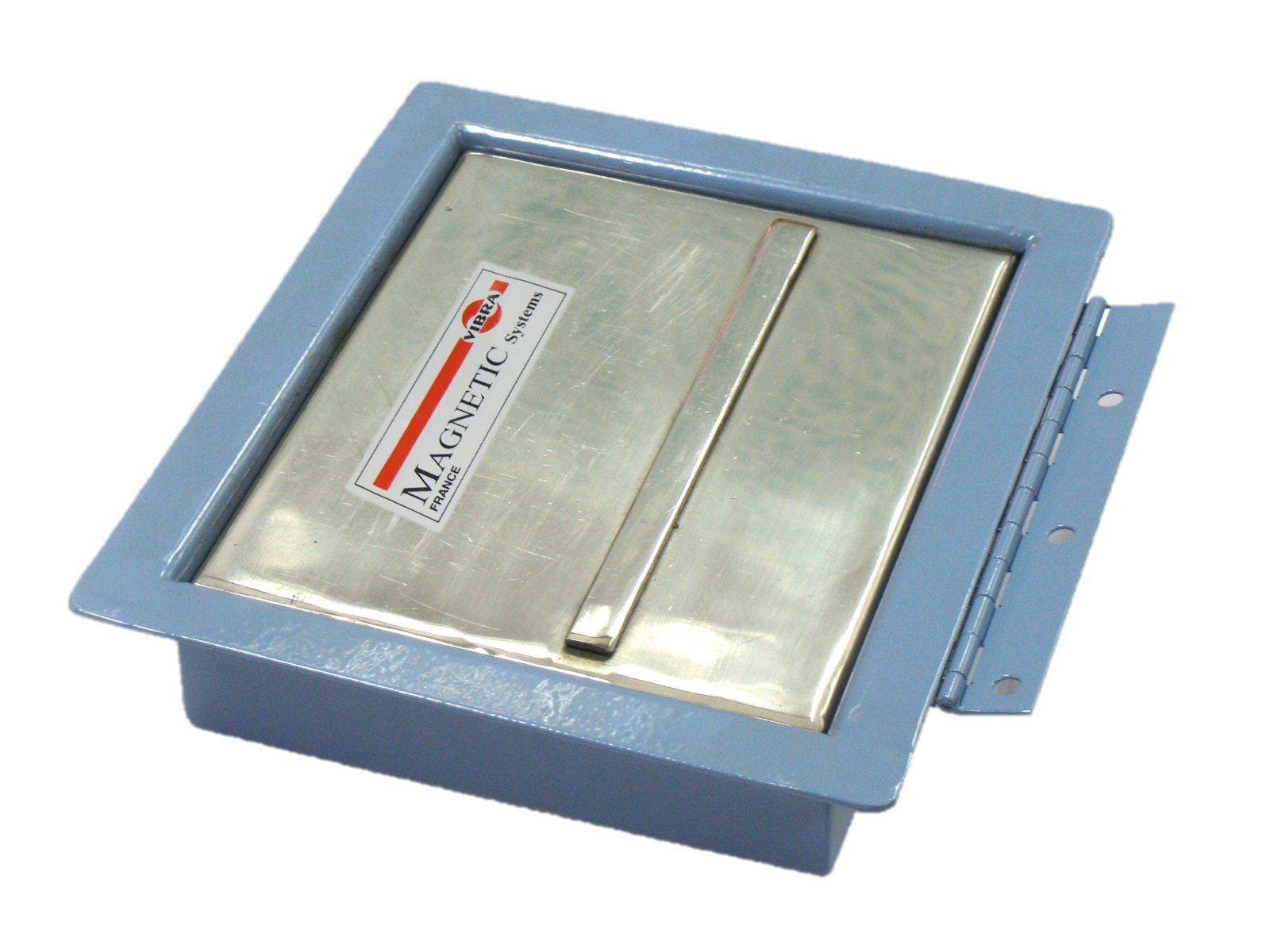

Plate Magnets

Plate magnets, such as the VIBRA® Plate magnets, are used in the following ways:

- At the bottom of an inclined chute

- Installed above conveyor belts

They are used to get rid of ferrous impurities that occasionally emerge in production processes, especially big pieces of metal like:

- Nuts

- Bolts

- Staples from dry goods

Grate Magnets

Magnetic rods in grate magnets are positioned in a grid to enable the material to tumble through a grate. They distribute magnetic protection through equipment parts with cross sections, like pipelines or hoppers. Grate magnets such as VIBRA® grate magnets can be used to remove fine or moderately large bits of metal impurities.

Liquid Line Trap Magnets

Traps with rod magnets inside are known as liquid line trap magnets, and they are made with an inlet port that is compatible with existing pipelines. The VIBRA® liquid line trap magnet gathers metal fragments, such as staples or baling wire.

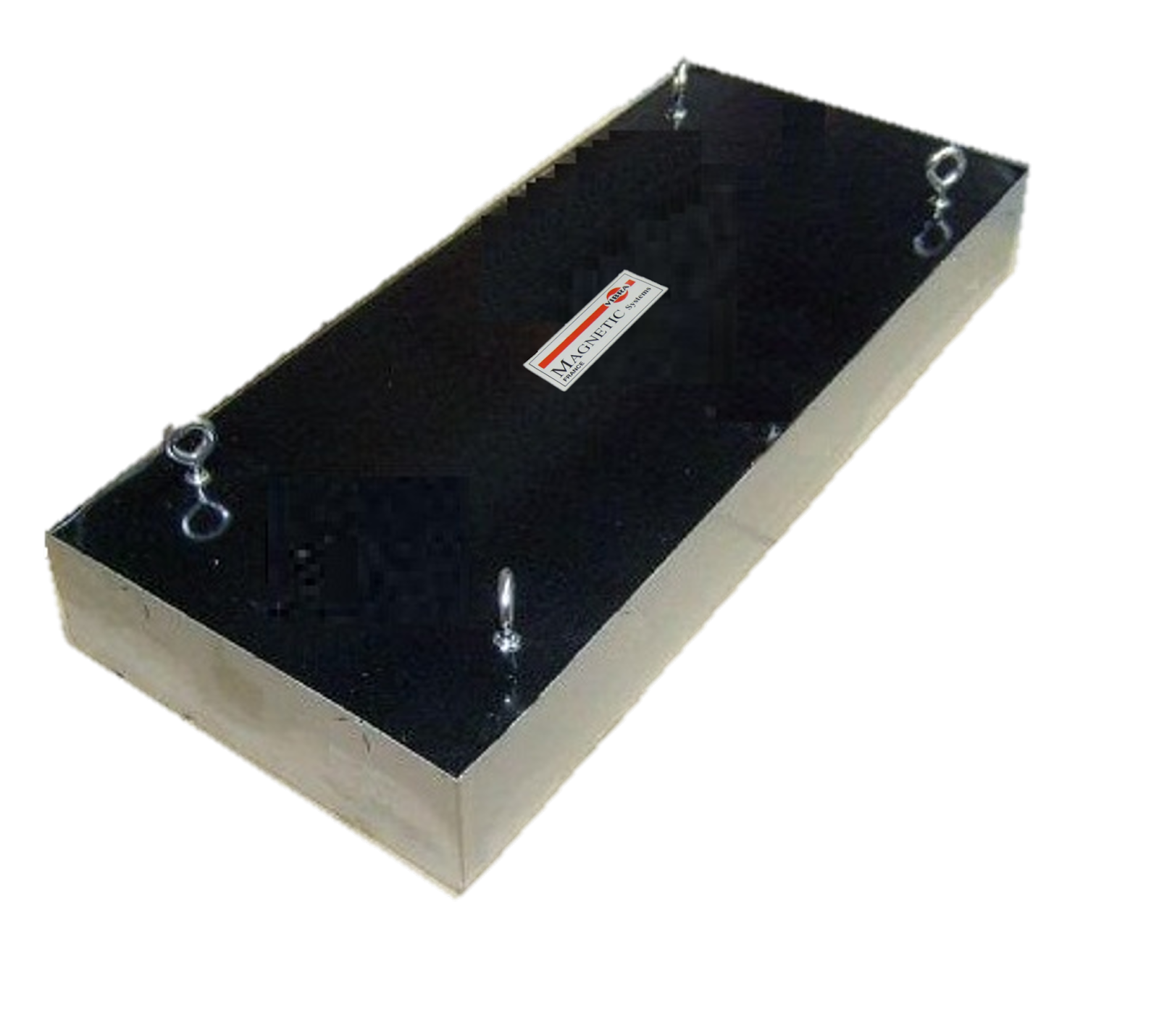

Suspended Magnets

Metal pieces are removed from the product when it passes beneath suspended magnets, which hang above conveyor belts. For example, with VIBRA® suspended magnets, large metal pieces are removed and can shield machinery like crushers from damage.

Why Are Magnetic Separators Important?

Each year, tons of food products are recalled as a result of customer discoveries of foreign materials or physical contamination. These recalls not only cost businesses millions of dollars, but they may also harm their image and endanger the safety of the general public.

Physical contaminants come in a wide variety and can be harmful if swallowed. For the industry that has long been involved in the topic of food safety and has been significant to all food production businesses, the prevention of metal contamination in food is an important issue.

So, here are some reasons why magnetic separators play an important role in the food industry.

Magnets Detect Contaminants We'd Normally Miss

You might be curious as to how ferrous substances and components end up in a facility that processes food. Many different things can produce metal shavings and particles.

A farmer's metal harvesting tools are one potential source because fragments can splinter off the shovel's blade and wind up in the delivery of goods.

The facility is another potential source. There are probably a number of moving pieces of equipment in a facility where nuts and bolts could come loose and fall into the mechanical processing or preparation lines. Due to the contaminant's small size, there is a considerable likelihood that processing personnel would miss it in each of the situations above.

Before an employee even realised something was amiss, a magnetic separator would draw the contamination.

Early Contamination Reduction and Crisis Prevention Are Better

In an effort to get rid of impurities as soon as possible, most food processing facilities start their operation with magnetic separators. Magnetic separators may also be used at the start, middle, and end of a process at some facilities.

In either case, a facility needs to have at least one magnetic separator. Additionally, removing pollutants is essential for a successful business because consumers demand a clean environment.

Where To Get Magnetic Separators In Malaysia?

Sematic Magnet is a reputable magnet manufacturer. We are involved in researching, designing, developing, and manufacturing a variety of the following products, such as:

- Permanent magnetic separators

- Industrial permanent magnetic products

- Magnetic tools

- Electromagnets

- Other related magnetic equipment

We provide standard and custom-made Permanent Magnetic Separators for most industries to attract and remove tiny iron particles from liquid or dry processing lines. Some of the industries include:

- Beverage and food

- Personal care

- Pharmaceutical

For more information about magnetic separators in Malaysia, contact us or speak to one of us today at +603-32917616.