Contact Us

Contact Details

-

Address

14, Jalan Sungai Batu Enam 50,

Klang Utama, 42100 Klang,

Selangor, Malaysia

-

Call Us

-

WhatsApp

-

Mail Us

+6012-2107616

Neodymium Magnets vs Ferrite Magnets: Key Differences

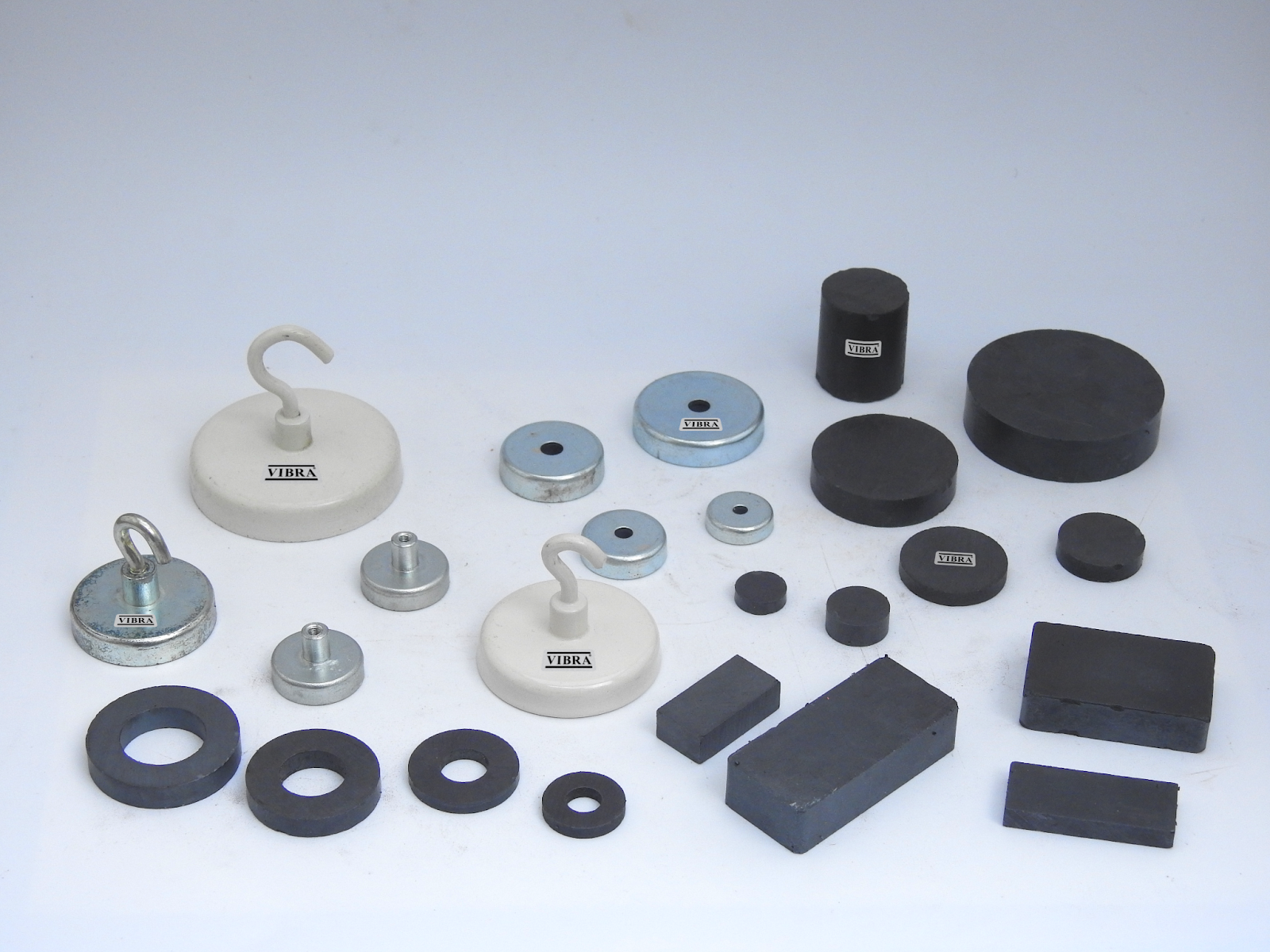

When it comes to choosing the right magnet for your machinery and application, it's important to understand the differences between ferrite magnets and neodymium magnets in Malaysia. Both have their unique advantages and disadvantages, making them suitable for different purposes. In this article, we'll delve into what neodymium and ferrite magnets are, their respective strengths and weaknesses, and how to select the right magnet for your needs.

What Is A Neodymium Magnet?

Neodymium magnets, also known as NdFeB magnets, are a type of rare-earth magnet. They are widely recognised for their incredible strength and are the strongest permanent magnets available. These magnets are composed of neodymium, iron, and boron, which make them exceptionally powerful.

Advantages of Neodymium Magnets

Neodymium magnets offer several advantages:

- Superior Strength - Neodymium magnets are incredibly strong, making them the most powerful permanent magnets available. They are perfect for applications where a strong magnetic field is required.

- Small Size - Despite their strength, neodymium magnets are compact and come in various shapes and sizes. This makes them suitable for applications where space is limited.

- Wide Temperature Range - They can operate in a wide temperature range, from extremely low temperatures to high heat, making them versatile for various environments.

- Wide Range of Shapes - Neodymium magnets come in various shapes, including discs, blocks, and rings, allowing for customisation according to specific needs.

Disadvantages of Neodymium Magnets

While neodymium magnets have many advantages, there are a few drawbacks to consider:

Brittle - Neodymium magnets are brittle and can break or chip easily if not handled with care.- Corrosion Prone - They are susceptible to corrosion when exposed to moisture and humidity. Coating or plating is often required to protect them.

- Expensive - Neodymium magnets are more expensive compared to ferrite magnets due to the cost of the raw materials used in their production.

What Is A Ferrite Magnet?

Ferrite magnets, also known as ceramic magnets, are made from a mixture of iron oxide and strontium or barium. These magnets have been in use for decades and are known for their cost-effectiveness.

Advantages of Ferrite Magnets

Ferrite magnets offer several advantages:

Cost-Effective - Ferrite magnets are much more affordable compared to neodymium magnets, making them a popular choice for budget-conscious applications.- Excellent Corrosion Resistance - They have excellent corrosion resistance and do not require additional coatings, making them suitable for outdoor and high-humidity applications.

- Low Energy Loss - Ferrite magnets have low energy loss over time, making them a reliable choice for long-term applications.

- High Curie Temperature - They can withstand higher temperatures without losing their magnetic properties.

Disadvantages of Ferrite Magnets

Ferrite magnets come with their own set of disadvantages:

Lower Magnetic Strength - They are not as strong as neodymium magnets, which limits their use in applications that require a strong magnetic field.- Bulkier - Ferrite magnets are bulkier and less versatile in terms of size and shape compared to neodymium magnets.

- Limited Shape Options - They are typically available in simpler shapes like discs, blocks, and rings, limiting customisation options.

Differences Between Neodymium Magnets vs Ferrite Magnets

Now that we've looked at the characteristics of neodymium and ferrite magnets separately, let's delve into the key differences between these two magnet types.

Strength

Neodymium magnets are the clear winners in terms of magnetic strength. They are capable of producing a much stronger magnetic field compared to ferrite magnets. If your application requires a powerful and concentrated magnetic force, neodymium magnets are the way to go.

On the other hand, ferrite magnets, while less powerful, are still quite capable in many everyday applications. If extreme strength isn't necessary, ferrite magnets can provide adequate magnetic force at a more budget-friendly price point.

Size

Neodymium magnets are compact and space-efficient, making them an excellent choice for applications with limited room. Their smaller size allows for more precise and streamlined designs.

Ferrite magnets, in contrast, tend to be bulkier due to their lower magnetic strength. This can be a disadvantage when space is a concern, as they may not fit into tight spaces as easily as neodymium magnets.

Cost

When it comes to cost, ferrite magnets have a clear advantage. They are much more budget-friendly compared to neodymium magnets. If you have a project with tight budget constraints, ferrite magnets are a cost-effective solution.

Neodymium magnets are more expensive, primarily due to their superior magnetic strength. However, the higher cost may be justified if your application requires extra magnetic power.

Application Versatility

Neodymium magnets offer greater versatility in terms of application. Their exceptional strength and compact size make them suitable for a wide range of uses, from small consumer electronics to industrial applications. If you need a magnet for various purposes, neodymium magnets are a versatile choice.

Ferrite magnets are less versatile due to their lower magnetic strength and bulkier size. They are better suited for applications where extreme strength is not a requirement, such as in speakers or refrigerator magnets.

How To Choose The Right Magnet

Selecting the right magnet for your application ultimately depends on your specific needs and budget. Here are some key considerations to help you make the best choice:

Strength Requirement - Determine the level of magnetic strength your application demands. If you need a powerful magnetic field, neodymium magnets are the way to go.- Space Constraints - Consider the available space in your application. Neodymium magnets are ideal for compact designs, while ferrite magnets may be more suitable for larger spaces.

- Budget - Assess your budget constraints. If cost is a significant factor, ferrite magnets offer a more economical solution.

- Application Type - Think about the nature of your application. Neodymium magnets are versatile and suitable for a wide range of uses, while ferrite magnets are better for applications where strength is not critical.

- Environmental Conditions - Consider the environment in which the magnet will operate. Neodymium magnets are more susceptible to corrosion, so if moisture or humidity is a concern, you may need to take extra precautions.

Contact Sematic Magnets For All Your Magnet Needs!

Whether you need ferrite magnets or neodymium magnets in Malaysia, Sematic Magnet has you covered. Our wide range of high-quality magnets is designed to meet various application needs. Contact us today to discuss your requirements, and our experts will help you choose the perfect magnet solution. We're here to provide the expertise and products you need to make your projects a success.

Remember, when it comes to magnets, the choice between neodymium and ferrite depends on the specifics of your project. Sematic Magnet is your trusted partner for all your magnet needs, and we're ready to assist you in making the right decision.

Sematic Magnet Sdn. Bhd. specializes in consulting, providing solution, designing, and supplying full range of permanent magnetic separation systems, industrial permanent magnetic products, magnetic tools, electromagnet, magnet materials, electrical vibrators, pneumatic vibrators ,and other magnetic equipments.

Quick Links

Contact Us

+6012-2107616

©2022 Sematic Magnet Sdn Bhd. All Rights Reserved. Website Designed by Heroes Of Digital