Modifying Magnets: What To Know And Should You Do It

Magnets are indispensable components used in a wide array of industries, including electronics, renewable energy, healthcare, and manufacturing. While off-the-shelf magnets cater to most applications, certain situations demand specialised magnetic properties. In such cases, modifying magnets becomes an option worth exploring.

This article delves into the reasons for modifying magnets, the potential benefits, the types of magnets that can and cannot be modified, and alternatives, such as custom-made magnets. If your business requires magnetic devices in Malaysia, understanding the process of modifying magnets will empower you to make well-informed decisions.

Why Modify Magnets?

When it comes to meeting the specific requirements of various applications, off-the-shelf magnets may not always suffice. Here are some of the reasons behind modifying magnets and how this process can address unique challenges, offering tailored solutions for your business needs:

- Tailored strength. Off-the-shelf magnets may not always offer the precise magnetic strength required for a particular application. Modifying magnets allows manufacturers to customise the magnetic properties to achieve optimal performance.

- Size customisation. Different applications call for magnets of varying sizes. Modifying magnets enables the creation of custom-sized magnets, ensuring a perfect fit for specific devices or systems.

- Temperature resistance. In industries with extreme temperature conditions, modifying magnets can enhance their ability to withstand high temperatures, making them suitable for challenging environments.

- Magnetic field direction. Certain applications necessitate magnets with specific magnetic field orientations. By modifying magnets, manufacturers can align the magnetic field as required, improving device efficiency.

- Cost-effectiveness. Modifying readily available magnets can be more cost-effective than sourcing rare or specialty magnets. Businesses can save on production costs while still achieving desired performance.

What Are The Benefits of Modifying Magnets?

Modifying magnets goes beyond just customisation; it opens the door to numerous benefits that can significantly impact the performance and efficiency of devices and systems. These are the advantages of choosing to modify magnets:

- Enhanced performance. Modifying magnets allows businesses to optimise their magnetic properties, leading to improved overall performance in specific applications.

- Increased efficiency. Tailored magnets contribute to better energy conversion, reduced wastage, and enhanced operational efficiency, leading to cost savings and improved sustainability.

- Versatility. Customised magnets can be designed to cater to various applications, providing versatility and adaptability to meet diverse industry needs.

- Faster prototyping. Prototyping with modified magnets enables companies to test different configurations quickly, accelerating the development process and reducing the time to market for new products.

- Competitive edge. Customising magnets to achieve superior performance gives businesses a competitive advantage, enabling them to stand out in the market and attract more customers.

Which Magnets Can Be Modified?

While the idea of modifying magnets sounds appealing, it is essential to know which types of magnets can be easily modified. This section delves into the types of magnets that can undergo modification and various techniques used to customise their properties to suit specific applications.

- Ferrite magnets, also known as ceramic magnets, are among the most common types that can be modified. Their brittle nature allows for processes like cutting, grinding, or drilling.

- AlNico magnets, composed of aluminium, nickel, and cobalt, are highly machinable and can be modified using techniques like casting, sintering, and machining.

- Samarium cobalt magnets, known for their excellent temperature resistance and high coercivity, can be machined to achieve specific shapes despite being harder to modify than ferrite or alnico magnets.

- Neodymium magnets, also known as rare-earth magnets, possess exceptional magnetic strength. While more challenging to modify, they can be machined with precision tools.

Which Magnets Cannot Be Modified?

Not all magnets are suitable candidates for modification due to their unique properties and manufacturing processes. In this segment, we identify the magnets that cannot be easily modified and explain the reasons behind their limited customisability.

- Flexible magnets, made of ferrite or neodymium powders mixed with a synthetic rubber binder, cannot be easily modified due to their flexible and pliable nature.

- Bonded magnets are created by mixing magnetic powders with a binder, such as epoxy. Once formed, these magnets cannot be easily modified without damaging their integrity.

- Injection moulded magnets are produced by mixing magnetic powders with a polymer carrier material. Once the magnet is formed, further modification can be challenging.

- Sintered magnets are made by compacting fine magnetic powders and heating them to fuse the particles. Their high density and brittleness make them difficult to modify without specialised equipment.

What Are The Alternatives To Modifying Magnets?

In cases where modifying magnets is impractical, exploring custom-made magnets can be the ideal alternative. Here's why custom-made magnets may be the best choice:

- Customised design. Opting for custom-made magnets provides the freedom to design magnets that precisely match the required specifications for your application. Working closely with experienced magnet manufacturers allows you to develop a magnet tailored to your specific needs.

- Consultation with magnet manufacturers. Collaborating with magnet manufacturers who have experience in creating custom solutions can prove invaluable. They can help identify the most suitable magnet material and design for your application, ensuring optimal performance and efficiency.

- Prototyping services. Many magnet manufacturers offer prototyping services, enabling businesses to test and refine custom magnet designs before proceeding with full-scale production. This process ensures that the final product meets all requirements and performs as expected.

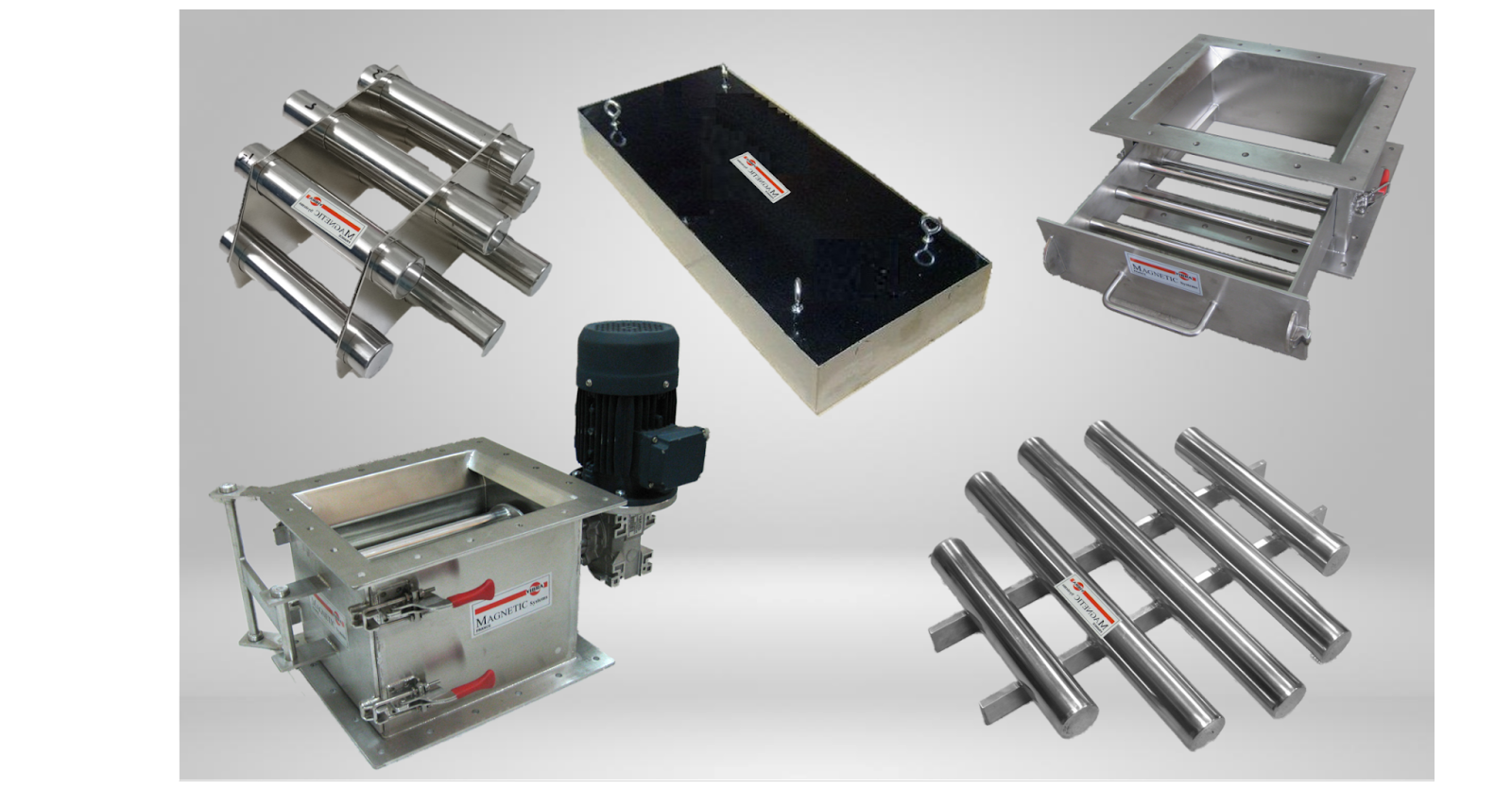

- Magnet assemblies. Instead of modifying individual magnets, magnet assemblies can be created by combining multiple magnets or other magnetic components to achieve the desired properties. Magnet assemblies offer flexibility and versatility in meeting complex application needs.

Looking for Customisable Magnets in Malaysia?

Modifying magnets can be a valuable solution for businesses seeking optimised performance and tailored solutions for specific applications. However, in cases where modifying magnets proves challenging or impractical, exploring the option of custom-made magnets through collaboration with experienced manufacturers remains an excellent alternative.

Making the right choice can lead to increased efficiency, improved performance, and a competitive edge in the dynamic business-to-business market. For more information, get in touch with

Sematic Magnets today.